In 3D printing, 3D modeling refers to the process of creating a mathematical representation of the surface of a viable object using specialized software. This technique is also referred to as 3D rendering. Typically, 3D printing devices can be used to create the models manually. The objects may also be created automatically where the entire modeling process of preparation is based on the geometric data of computer graphics. The 3D modeling software refers to a broad range of classes of various computer graphics software, usually in 3D, used to produce 3D models. The elements represent the body of a product using a broad spectrum of collection points in the 3D space. Designing perfect 3D model designs should not be complicated. In this article, we discuss the three quick tips to help you.

3D printing viably paves the way for geometric freedom in many ways. In the manufacturing world, it has enabled professionals to realize the possibility of developing intricate designs. Although the existing sculptures are plentiful, you may also take advantage of the empowering 3D model printing technology by designing your custom files. The method is tolerant of existing complex geometries. Besides, the designs created are printable. Having noted that, there are certain items, you should note regarding designing that will make your printing process smoother.

Here are the tips:

You Should Get Your Clearances Right!

If you want to design mechanical and fitting parts, then you need to get your clearances right. This is a crucial step in ensuring that the machine is precise. Because 3D printers may be less accurate compared to other technologies, you should ensure that you have proper clearances. The gaps found between each other should also fit. For example, if you have a design that can hold a bearing, then the hole created needs to be slightly more significant compared to the bearing.

Observe File Quality

Your 3D print design needs to be converted to a quality 3D printable file. In this case, you will need to take note of the following items:

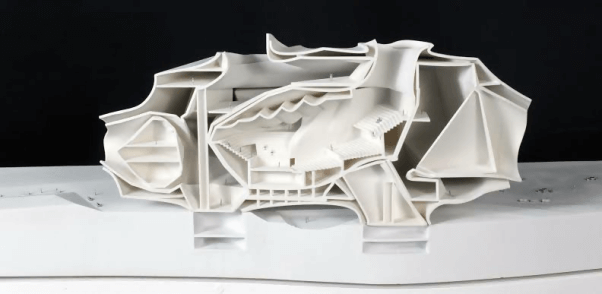

- Make sure that you have a quality converter. The image below is a perfect demonstration of the value of having high quality yet precise model designs based on the material used. This is important when you have slightly small features that can easily be omitted when the file quality is substandard.

- Ensure that your file is watertight before you proceed. Here, you should observe that it has no holes to confuse software used for slicing.

- The model should be scaled before exporting. The move will play a significant role in preventing detail loss that may be caused by scaling the model up.

You Should Comprehend The 3D Printing Technology

3D printing comprises of various technologies. Every type has an added advantage. You need to understand the entire processes involved in creating a model design from your 3D printer. Reflecting these technologies in your plan is going to give you a smoother printing experience. To shed more light to this point, we have highlighted a few 3D printing technologies below:

- Stereolithography ( is also known as SLA) – this is a printing technology used in the creation of prototypes and patterns for various production parts using photochemical processes. The additive manufacturing process focuses a laser on the polymer resin.

- Fused Deposition Modeling- Fused deposition modeling is also known as FDM. It is a prominent additive manufacturing process used to fabricate prototypes as well as functional parts, particularly in engineering plastic. The entire process is usually based on extruding feedstock plastic filaments via a nozzle.

In Closing

After reading this article, you should now be ready to venture into 3D printing models! The tips above are simple. However, they also go a long way when it comes to easing the printing process. With these methods, you should have quality 3D print models. Should you need assistance in selecting design tools, you can check out our series of blog posts on the best 3D model printing tools.