Rapid manufacturing or prototyping and some of the technologies including, moulding, extruding casting among others is simply using software to ease up and quicken the manufacturing process and involves CNC machining and 3D printing while traditional manufacturing refers to the principles that aid in a certain number of products and reserving in case of rise in demands or shortages in the near future. With a 3D printer you can enjoy fast turnarounds at a relatively lower cost. Although CNC machining uses subtractive manufacturing hence a lot of waste, it still has a key role in manufacturing processes. Rapid manufacturing overtakes traditional manufacturing in several ways which includes:

Even less waste.

Additive manufacturing gets rid of unnecessary material waste hence saving on the material cost this is because it adds product from scratch. 3D machining takes the elimination of secondary machining to a higher level. Less waste will ensure that your production process is cost efficient.

Manufacturing and assembly at once.

This helps in combination of manufacturing and assembly into a single process. This evades the need to create parts individually then assembling them later on and instead obtaining multiple components at a time.

Rare shape making ability.

One can create any shape be it hollow spaces and honey combs that can maintain stability while decreasing the weight hence once more 3D printing can be used as powder metallurgy.

Complexity is free.

The more complex a part is the easier and faster it can be made through the additive manufacturing method. 3D printing gives room for complex geometries since all you need is a CAD file.

Little skill manufacturing.

This has been certified in that children in the 3rd grade have created their own parts by the help of 3D printers while professionals take high concern on the complicated parts with specific parameters. Some machines can run for hours without human intervention. Since little human involvement is allowed, the risk of human errors is eliminated meaning that quality is ensured.

Little lead time.

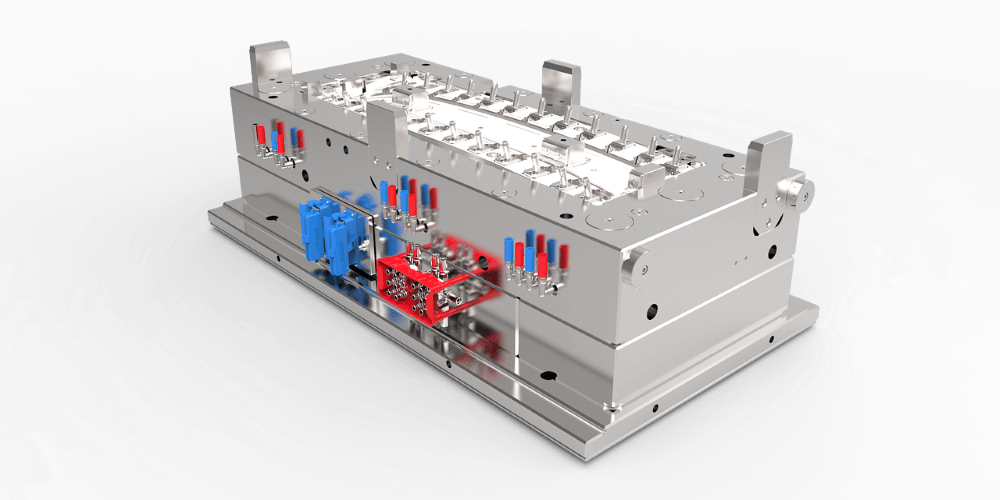

After completing stereolithographic file, instead of waiting for ages for a prototype to come engineers can create a prototype with the help of 3D printers. In a fast paced market, prototyping requires fast production means. A good example is the plastic market. In the plastic industry you need to have a short production cycle if you are to survive. Injection molds used to take ages especially if they were made from hardened steel, not to mention how expensive steel is.

Few constraints.

With the help of additive manufacturing one can create something exactly how he or she imagined it. You can further replicate your design to come p with identical parts.

However, rapid manufacturing has some disadvantages which include; post-processing is needed since it may have low quality than other manufacturing methods, poor mechanical properties especially on the layering, it is almost always cost prohibitive since it is not always effective, no mixing allowed and it is slow and niche among many more.