CNC machining has many benefits to offer. These include waste reduction, precision, and efficiency. However, their main competitive edge is the versatility they provide. For instance, they can be used to cut materials in different applications and industries for both large-scale and small-scale production shops. The best CNC machines provide total versatility, efficiency, and precision to help shops produce outstanding results with minimal labor. The following are some of the effective applications of CNC machining.

Signage

It does not matter whether you want to create complex 3D or 2D signage components; with CNC machining, you can complete your project quickly. Remember that CNC routers can work with various materials that include wood, plastic, brass, aluminum, and more.

Machines with a vision system provide enhanced accuracy and efficiency for users who want to register the tool path when making carvings or signage. Also, it is possible to make government compliant signage that is needed for modern sign shops. The use of CNC machines makes it possible to produce results that feature tactile text, character spacing, and braille. With precision machining services, you can do this and more. You have the freedom to use photographs or new designs.

Furniture and Cabinets

Cabinet and furniture manufacturing are common applications of the CNC machining. For instance, you can use this manufacturing technique to make standard or customized cabinetry. Also, the CNCs help shops to make closet sets, countertops, tables, chairs, panel doors, and more with unrivaled efficiency and immense precision.

Intricate furniture and cabinetry designs are brought to life through 2D, 3D, and 5-axis capabilities. In this way, you can make furniture with an elegant finish. The good thing about using CNC machines in making furniture is that it reduces material handling, lead times, and even elevates the quality of the cabinetmaking process through the use of high-end CNC machines.

Brass and Aluminum Machining

The ability to work with metals such as brass and aluminum increases cutting capability with the use of CNC machines. Moreover, with little preparation and attention, you can save money and time in the shop whilst producing superior results.

Utilizing and determining the ideal spindle RPM and federate is critical when working with brass and aluminum. That is because they interact differently with the blade as compared to other materials.

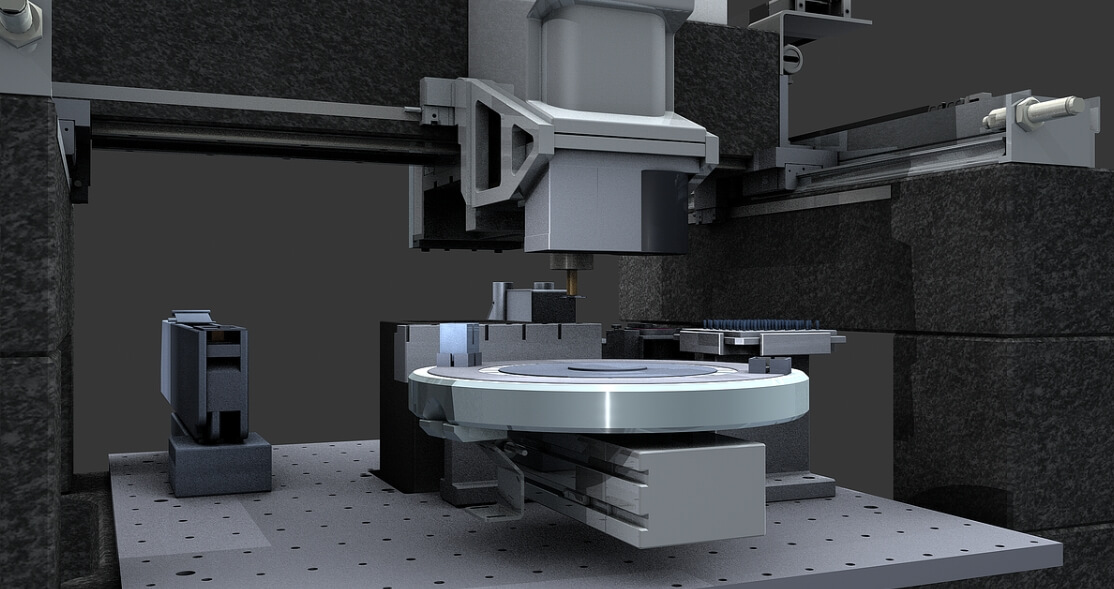

3D Modeling and Prototyping

Prototyping and modeling play a significant role in the success of your production process. If you cannot achieve precision, you cannot assess the potential of your concept. With CNC machining, you can engineer, reserve-engineer, copy, and scan components to help make advanced and innovative products. Also, production speeds of CNC plasmas and CNC routers allow you to meet project timelines as you accurately and quickly create prototypes that shape your decision-making.

Creating Musical Instruments

The use of CNC machines plays a critical role in manufacturing musical instruments. Remember that every component ought to be cut to the required specifications and even interact properly to make amazing sounds. With CNC routers, manufacturers can make high-quality musical instruments quickly without sacrificing the performance of the pieces. Also, they can be used to make customized instruments to meet the needs of customers.