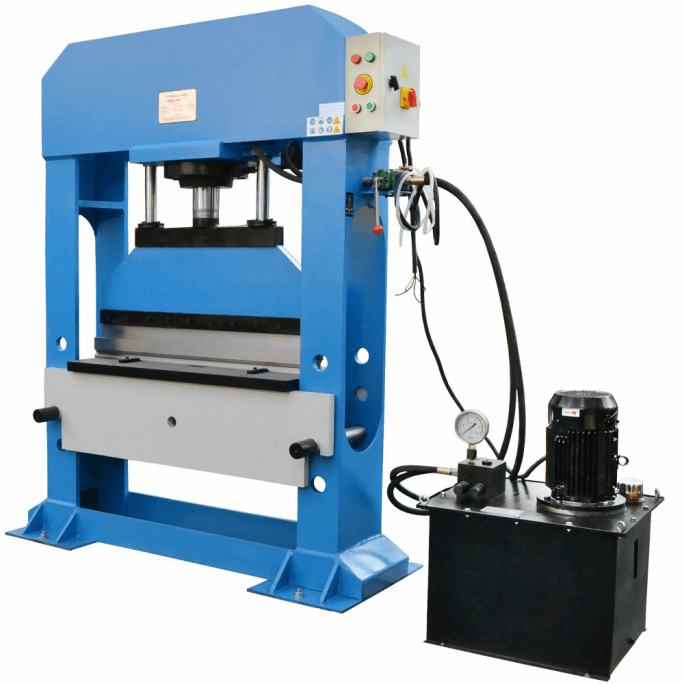

A press brake machine is ever-present in the manufacturing industry. Especially for the creation of machine parts is the press brake ( refer to MazakPower ). As a hydraulic press brake is a standard for mass production of parts, the processing range, performance, precision and function must be spot on. To help you do this and evade costly production mistakes, below are things to consider before investing in a hydraulic press brake.

- Hydraulic Press Brake Work Load

Unlike the use of a manual press brake, the use of a hydraulic press brake gets to calculate the workload force in its standard-setting automatically. It’s essential to consider the workable ton-force to ensure that the equipment will complete the processing task in time and without itself straining. Often, many people make the mistake of going for the shortest viable minimum ton-force. However, this usually needs replacement after some time. To help you choose correctly, consider the carbon sheet metal you are going to produce and calculate the suitable processing range, performance, precision, and function.

- Hydraulic Press Brake Deflection

Even though deflection is a common aspect during the bending process, it is vital to consider the exact estimate when looking for a press brake machine for sale. The deflection of the device is usually dependent on the length of the piece as the longer it is, the higher the deflection is. As a result, consider if the press brake you want to invest in takes into consideration the reflection process as this reduces the adjustment of the machine by the operator.

- Texture Of Material The Hydraulic Press Brake Is Working On

As expected, the texture of the material being bend significantly affects press brake operation and hence need different bending force. For example, low carbon steel requires a higher bending force when compared to soft aluminum sheets. Fortunately, most press brakes include standard bending pressure parameters. However, if you are working on something unique, you should ensure you purchase a press brake with the correct bending force.

- The Desired Hydraulic Press Brake Bending Angle

Considering the press brake machine bending angle is essential if you want to invest in a machine with the lowest tonnage. The bending radius has to be considerably more extensive than the sheet metal thickness to achieve this. To give you flexibility in the bending process, choose free bending as this will guarantee extended machine service as it won’t affect the quality of the finished product,

- The Hydraulic Press Brake Bending Accuracy

When making different machine pieces, the parameters for the parts need to be accurate. To achieve this, consider the parts that you want to manufacture. Often, you can get away with a 0.5-degree variance. However, to achieve this, ensure that the ram repositioning is adjustable to a degree of 0.01mm variance for high accuracy and performance.

Conclusion

As the press brake is a crucial element in the creation of various parts of a machine, you must select a device that meets your specifications. Conduct extensive research on the different kinds of hydraulic press brake and choose one that is most suitable to use. As a result, you get to choose a machine that serves you well and save you money.