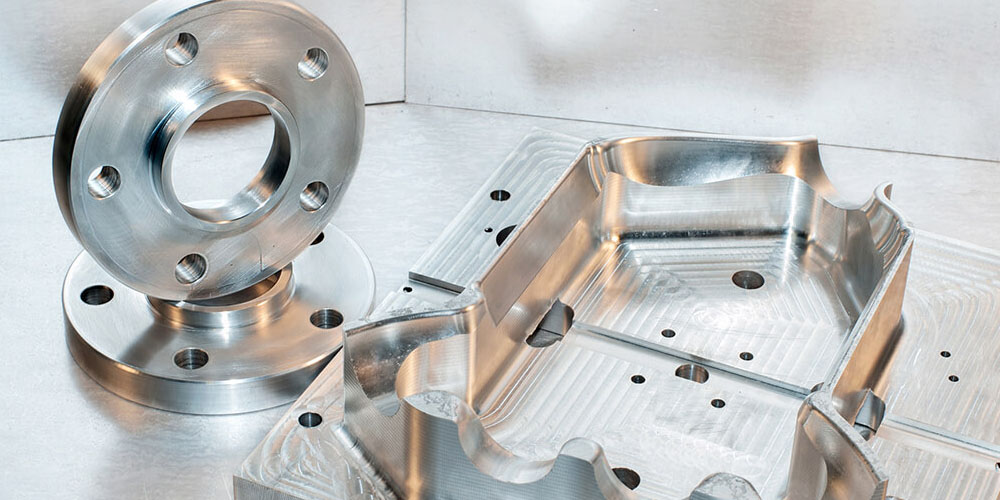

Ddprototype is a CNC posted service provider. The company has made a name for itself in China for offering the best CNC machining, CNC milling, rapid prototyping, and aluminum anodizing services. Ddprototype guarantees quality and efficient services to clients from various industries. The company’s anodizing aluminum services are highly beneficial. In this write-up, we discuss anodizing aluminum benefits.

Benefits of anodizing aluminum

You may not realize it, but you interact with a wide range of anodized products every day. This is because the technique is used for a wide range of parts like handheld devices. Its wide range of applications can be attributed to its benefits. Below are some of the main benefits of anodizing aluminum;

1. Enhanced durability

One of the primary and arguably most important benefits of anodizing aluminum is that it enhances its durability. The aluminum oxide coating formed during the anodizing aluminum process makes the surface hard and less susceptible to damaging elements like scratches and corrosion.

2. It prevents corrosion

The barrier or protective layer helps prevent further oxidation of the aluminum part. This is because aluminum oxide is a stable element. Additionally, the layer is also resistant to scratches.

3. It prevents chemical reactions

The barrier layer (aluminum oxide) is highly resistant to chemical reactions of any kind. This is because aluminum oxide is an extremely stable element. This means that it does not react with other natural elements of salts. Even at high temperatures, the surface maintains this property.

4. It helps enhance the appearance of the aluminum part

It is also worth mentioning that anodizing your aluminum parts allows you to paint over them without worrying about the paint peeling off. This happens because the colorant steeps into the pores formed on the anodized surface. This makes it impossible for it to peel or chip.

5. The process is eco-friendly

Another benefit of anodizing aluminum is that it is eco-friendly. This means that it does not emit any chemicals or harm the environment in any way. Additionally, the process produces an environmentally friendly finish. This means that the anodized aluminum parts can be reused or recycled. Therefore, you do not have to worry about disposing of them.

6. The technique is affordable

It is also worth mentioning that anodizing aluminum is an affordable technique. Compared to painting and powder coating methods, you do not need to spend much time and money on anodizing aluminum techniques. In this process, all you need is an electrolyte solution and electric current. There also isn’t much human labor required for the process.

How hard is anodized aluminum

Most people assume that the coating has to be hard to provide the benefits mentioned above. However, the coating is usually thinner than paint. For this reason, anodized parts are usually lightweight. Regardless of their size of the layer, it still makes the parts hard. According to Mohs scale of hardness, anodized aluminum features a rating of 9 out of 10. The only metal harder than anodized aluminum is diamond.

Final word

It is worth mentioning that oxide layers are usually harder than their base metals. This means that the barrier layer on the anodized aluminum is harder than raw or bare aluminum. For this reason, anodizing is highly applied in various industries.