Flexographic printing has become very popular over the years due to its technological advancement. The flexo equipment has excellent functionality, rapid speed and produce high-end products that are appealing to clients. One would prefer reasonably priced goods for mainly personal, family, or other needs. The flexographic printing technology offers just that since total costs are usually low and profits are high. In this write-up, we look at the components that make up a flexographic machine.

Components of a Flexographic Machine

For label printing to happen, some components have to be present for the equipment to operate. They all pose similar features; hence it’s essential to understand whether you plan to buy or operate one. They include;

1. Printing Station

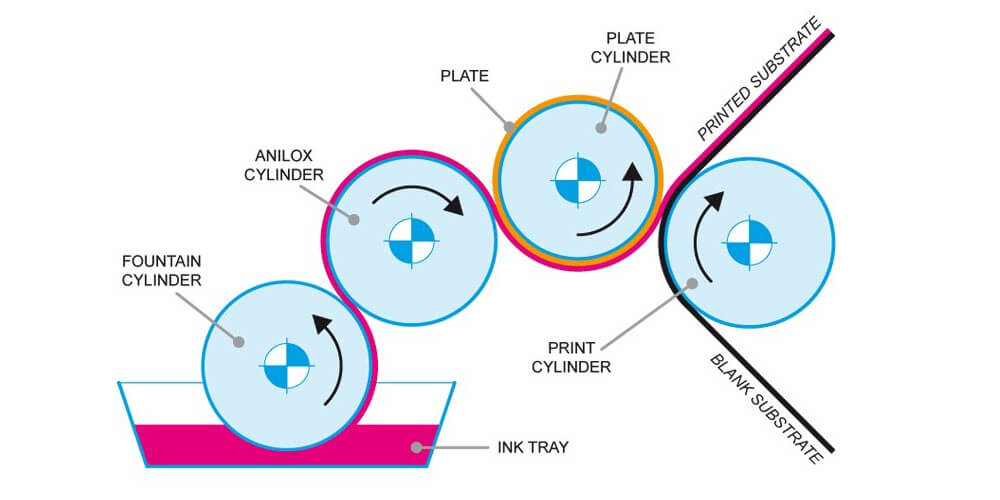

The flexo printing station should be smooth and firm, i.e., stable to ensure the printed images are not affected by any vibration. Each image should match the original one; thus, the printing must be consistent. Printing stations are available for each color. A variety of processes take place in this station, including;

- The anilox cylinder is fed through the inking system.

- Transfer of ink from the system to the plate

- Feeding of the substrate between the press plate and counter-pressure cylinder

- Passing of the substrate through the dryer and then taken to the next printing station

2. Feeding and Unwinding Station

The substrate is fed into the press plate using this component. It controls the tension, keeping it even throughout the process. The unwind system usually comes with a web guide that helps in cleaning the equipment. Treaters are an essential part of this feature as they treat substrates such as synthetics, doing away with bacteria or harmful substances that may be risky to people.

3. Drying Station

Every substrate passes through the dryer for the ink to dry. The same color can get applied again to achieve the desired saturation levels and get a solid color, or a different one can be used. Flexographic printing is known for its high production speed; hence, the intensity levels while drying should match the machine’s speed. Each application’s speed varies, but good machines will allow the press plate’s intensity and speed to be uniform. This station can include an Infrared or Ultraviolet (UV) fan for quicker drying.

4. Die Cutting and Converting

It is used to develop custom print shapes and labels. The designs you have dictate the process of die-cutting. They are converting aims at increasing the speed and performance of the die-cutting procedure. Products are produced in a sheet form, and this is common with narrow web presses. This entire process requires high-pressure levels, and robust, heavy-duty machines are needed to facilitate the printing and avoid breaking down.

5. Outfeeding and Rewinding

This is the final stage of the printing press, and the substrate exits at this point. The tension is still controlled by sensors, which play a significant role in enabling the leaving process. Rewinding helps remove the waste materials out of the system, and the end products are kept in rolls to be inspected before selling them out.

Conclusion

Each component of the flexo machine plays a huge role in the printing process. The points above will help you understand what they are and how they work for more effortless operation.